How can Companies Combat the Electronic Components Shortage?

The ongoing shortage of electronic components continues to disrupt businesses across the country. When combined with other current supply chain crises, such as increasing port congestion and a truck driver shortage, the shortage has made electronics device manufacturing much more difficult.

These strategies may be the most effective for businesses navigating the shortage until the market is able to provide more normal levels of supply.

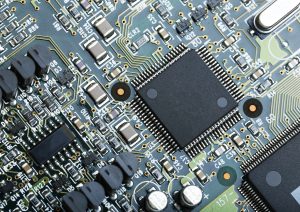

A number of major component types are currently in short supply.

The most serious shortage is one of the semiconductors, which is being caused by a combination of impending Covid-related manufacturing disruptions, limited availability of critical semiconductor materials, and rising demand for electronic devices.

Despite slower-than-expected economic growth, demand for semiconductors increased by more than 30% between August 2020 and August 2021.

The growth of the IoT market, the development of technology such as the IoT semiconductor, and the rollout of 5G are all likely factors in this surge in demand.

The pandemic and current supply chain challenges have also impacted the availability of key passive and power supply components such as multilayer ceramic capacitors (MLCCs), diodes, transistors, and resistors. These components, like semiconductors, may be difficult to obtain.

When will the scarcity end?

Experts are unsure how long any of this component scarcity will last. Many experts predict that manufacturers will see some relief in 2022.

Sectors like the automotive industry, which did not work as hard to maintain connections with electronics component manufacturers during the pandemic, may not recover until early 2023. In any case, businesses should expect electronic and component shortages to last well into 2022.

What businesses can do now to adapt

Businesses are implementing innovative strategies to deal with the current shortages. Some of these strategies are applicable to multiple industries and sector niches for example, building stronger relationships with component suppliers, can benefit all businesses.

Developing supplier relationships

Regular communication with the suppliers may provide the most recent market update, advance notice on part availability, and possibly advice on navigating future shortages.

Businesses that maintain relationships with their suppliers will likely have an easier time recovering once the shortage is over. Many suppliers also provide preferred customer programs and other initiatives that give customers priority if they commit to long-term business relationships. If a company can afford to sign a six-month or longer contract, it may be able to secure a supply of critical components for the foreseeable future. Building resilience in a company’s supply chain can also help it prepare for future crises. Diversifying suppliers, increasing storage capacity for critical components, and investing in risk management can all help a brand protect itself from future supply chain shocks.

In any case, when trying to manage current shortages or diversify their supplier base, businesses should avoid grey-market and unofficial suppliers. These suppliers’ and resellers’ quality and reliability may be lower than that of more legitimate suppliers, even if they can provide chips when other manufacturers cannot.

Changes to product design modifications and manufacturing process.

Manufacturing and supply chain issues may also necessitate more immediate solutions for businesses. Companies that are unable to obtain their desired chips, for example, may require temporary chip replacement.

One possibility is to replace current chips with chips that have more or less memory than the current solution. Larger chips may necessitate budget adjustments, whereas smaller chips may only work with new firmware that requires less memory.

Designing for shortages may be the only short-term solution to certain product availability issues, particularly in industries that may not see relief until early 2023.

Preparing new designs for potential shortages can also assist businesses in preparing for future crises. Open-ended designs that can be easily reconfigured based on component availability may help keep production flexible, allowing the business to move quickly if a preferred chip or component becomes unavailable due to shortages.

Businesses that plan ahead of time can avoid the shortage of electronic components.

Experts predict that the electronic component shortage will last until 2022 — and possibly beyond if industries do not maintain strong relationships with suppliers.

Until then, it’s possible that raw materials and components like semiconductors, transistors, and resistors may continue to be in short supply.

With proper planning, firms can navigate the crisis and get ready for any supply chain shocks in the future. Stronger supplier partnerships, a diverse supply base, and flexible designs could all contribute to reducing the shortage.

Conclusion

Here at Escronics, we enjoy the thrill of bringing old tech back to life. So if you are looking for obsolete electronics components that are no longer supported by the manufacturer who made them, we’re sure you can find them with us.